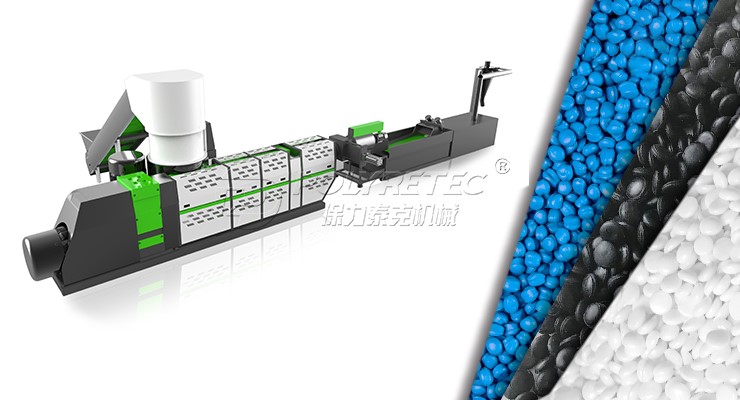

Plastic Film Bag Granulating Recycling Machine Line

Ⅰ. Plastic film bag granulating recycling machine line features:

- Plastic film bag granulation recycling machine line with high output and excellent granulating ability (200kg/hour to 1000kg/hour)

- Plastic film bag granulation recycling machine line is widely used to recycle waste plastic PP PE BOPP LDPE HDPE Film Bag into PE PP pellet

- Simple structure, easy operation, large capacity, energy-saving, safety, eco-friendly way

- Automatic controlling, compacted structure, excellent production ability, perfect granulating ability

5.Processing material: food packaging film, agriculture film, green house using film, PP bag, HDPE film, LDPE shrink film, printed film, oily bag, etc.

6.You can choose single stage (one extruder with one screen changer) or double stages (mother-baby two extruders with two screen changers) based on raw material clean degree & real production needs

7.You can choose water-ring cutting or cold-strand noodle cutting way to match different raw material

Ⅱ. Plastic film bag granulating recycling machine line detail list:

No. | Name | Qty. |

1 | Belt conveyor & metal detector | 1set |

2 | Compactor / Agglomerator | 1set |

3 | Single screw extruder(one stage or double stages) | 1set |

4 | Hydraulic screen changer | 1set |

5 | Plastic pelletizing system(water-ring cutting system) | 1set |

6 | Dewatering machine | 1set |

7 | Air transmission and silo storage | 1set |

Cold-strand granulating way also available with rich experience, based on raw material condition.

Ⅲ. Detailed description for plastic film bag granulating recycling machine line:

Process flow of plastic film bag granulating recycling machine line:

Feeding conveyor belt →metal detector(optional) → compactor/agglomerator→single screw extruder(first stage) →hydraulic screen changer→ single screw extruder(second stage)→ hydraulic screen changer→water-ring cutting system→water cooling tank→dewatering machine → vibrator(optional) → air conveying→storage silo

Application of plastic film bag granulating recycling machine line:

Applicable plastics material:

PE, PP, BOPP, HDPE, LDPE, LLDPE, etc.

Material shapes: food packaging film, agriculture film, green house using film, PP bag, HDPE film, LDPE shrink film, printed film, oily bag, etc.

Note: Depending on material property, various downstream machine are available

PE PP film bag granulating recycling machine running in customer's factory

Machine list

Belt conveyor

1) Belt material: PVC

2) Speed adjusted by inverter, synch running with agglomerator

3) Height adjustable

4) Equipped with wheels

5) Equipped with tightening device

6) Metal detector for option

![]()

- Double-layer cutting- disk, patent design, more efficient in feeding.

- Special arrangement of blade & feeding mouth, output is increased by 10%-20%

- Hydraulic Opening and Hydraulic Lifting, safe and easy maintenance

- Our method of cooling wall of agglomerator: by air and water cooling system, No need to add water into the agglomerator.

- Double-layer cutting-disk

Output is increased by 10%-20%!

Double-layer cutting-disk:

Double-layer cutting-disk design, the upper cutting-disk is preheating, the lower cutting-disk increases the compression space, increases the friction coefficient, the temperature rises fast, the feed is stable, and the output is increased by 10%-20%, especially for raw materials with low bulk density.

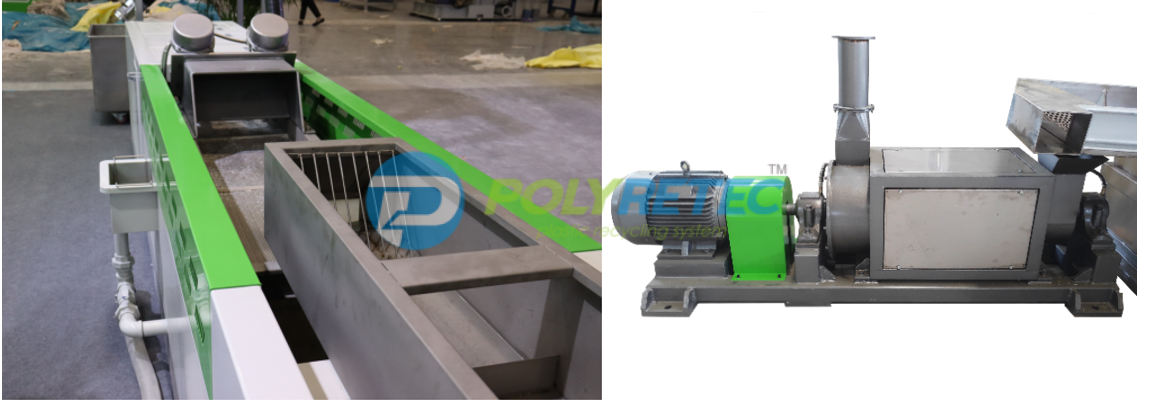

Single screw extruder (First stage)

1st extrusion, 1st filtering

![]()

- Gearbox: high quality Chinese brands or based on customer’s request

- Frequency inverter: Siemens brand

- Screw & barrel: 38CrMoAl, Nitride with thickness 0.4 ~ 0.7 mm, Polish

- Heater: Ceramics + stainless steel cover

- Vacuum pump exhaust, double exhaust

- Self-protective system:

Over current protective of motor

Over pressure protective of screw

Over temperature protective of motor

Low & over temperature control of extruder - Screw & barrel are specially designed by our engineer according to decades years’ experience for good plasticizing effect & capacity.

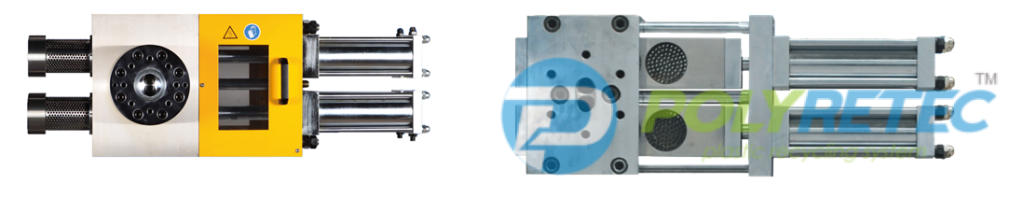

Screen changer

Multiple choices for different materials.

- Material for mold body: 40Cr

- Nitriding and polishing of runner surface

- Pressure and temperature control

- When pressure is nearly reach alarm value, hydraulically change to another station.

- High filtering effect, realizing non-stop screen changing

- No leakage, automatic gap compensation

Single screw extruder (Second stage)

2nd extrusion, 2nd filtering, to achieve better granule quality

Water-ring cutting system

Quantity of Blade: 2-4, SKD-11

Speed controlled by inverter

Material of die head: 38CrMoAlA

Material of water ring cover: Stainless steel 304

Horizontal design with linear guide, easy operation and maintenance.

Pneumatic adjustment, to make cutting blades and die-face soft touch, in order to achieve 100% contact between the blade and die head, to avoid die face damaged.

Dewatering Vibrator

1.Linear vibrating screen uses vibrating motor as the vibration source, so that the pellets are thrown up on the screen, and move linearly forward. Several sizes of screens are equipped for pellets discharging from their respective outlets.

2.Linear screen fully enclosed structure, no dust and overflow, automatic discharge, etc., more suitable for 24-hour assembly line operation.

3.Linear screen by low energy consumption, high output, simple structure and easy maintenance.

4.Combination of filtration and dehydration, high efficiency and power saving.

Silo

Part of contacting material: stainless steel 304

Control cabinet

Independent operation panel for

easy operation, English version

With cooling fan inside

Temperature controller: Omron

Frequency inverter: Siemens

Self protective system:

Over current protective of motor

Over temperature protective of motor

Over pressure protective of screw

Low & over temperature control of extruder

Plastic film bag granulating recycling machine line detail list:

No. | Name | Qty. |

1 | Belt conveyor & metal detector | 1set |

2 | Compactor / Agglomerator | 1set |

3 | Single screw extruder(one stage or double stages) | 1set |

4 | Hydraulic screen changer | 1set |

5 | Plastic pelletizing system(water-ring cutting system) | 1set |

6 | Dewatering machine | 1set |

7 | Air transmission and silo storage | 1set |

Cold-strand granulating way also available with rich experience, based on raw material condition.

Detailed description for plastic film bag granulating recycling machine line:

Process flow of plastic film bag granulating recycling machine line:

Feeding conveyor belt →metal detector(optional) → compactor/agglomerator→single screw extruder(first stage) →hydraulic screen changer→ single screw extruder(second stage)→ hydraulic screen changer→water-ring cutting system→water cooling tank→dewatering machine → vibrator(optional) → air conveying→storage silo

Application of plastic film bag granulating recycling machine line:

Applicable plastics material:

PE, PP, BOPP, HDPE, LDPE, LLDPE, etc.

Material shapes: food packaging film, agriculture film, green house using film, PP bag, HDPE film, LDPE shrink film, printed film, oily bag, etc.

Note: Depending on material property, various downstream machine are available

Sales service

- Pre-sale: we give customer the plastic recycling machinery detail technician offer, sign the sales contract etc

- In-sale: we supply the plastic film bag granulating machine (together with crushing washing machine if needed as a recycling system) layout, installation, technical support. Running the plastic film bag granulating recycling machine line before delivery.

After customer’s acceptance,we arrange the related machine delivery rapidly, provide detailed packing list and related documents for customers' customs clearance.

- After sales: we arrange our experienced engineer to install the machinery and training the workers for customer in customer factory.

- We have 24 hours team to support the after-sales service

- We have free spare parts with the machine when we deliver the machine.

We supply long-term spare parts for every customer with cost price

- We always update the new technology to every customer

- FAQ for our plastic recycling machine

- How can I get fast response of products?

You can send mails for our products details, and also we’re available in fast talking tool such as wechat, whatsapp, viber, linkedIn, facebook, etc.

- How soon can I get a quotation?

For most projects, once we know the necessary information of the recycled raw material , we can provide you with a quotation within 24 hours.

- Can I have a customized design?

We design and construct each project according to customer's needs.

Customized is based on request (For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V50Hz....)

- Is there a minimum order requirement?

Caused by the daily production capacity is very huge and shipping freight, our minimum order quantity is 1set, but we can help to do several colors for choice. It is recommended for you to order a 20”GP or 40”HC to reduce the unit price and shipping cost.

- What are your office hours?

You can reach us between the hours of 8:00 A. M. and 5:00 P. M. GTM+8, Monday to Saturday, except Chinese national holidays.

- Do you have a price catalog?

We are a professional plastic recycling machine manufacturer. We have different models even for same material type recycling machine, suggest to ask price/quotation based on real needs(e.g. capacity or your rough budget).

7.How do I know I can trust ordering from you?

We have been in business since 2003 and are committed to bringing our customers 100% satisfaction. You can visit them if the customer allows the visit.

Suzhou Polytec Machine Co., Ltd is a competitive manufacturer in producing customized plastic recycling machine (shredding, crushing, washing and granulation machines). Such as PE PP film washing and granulation machine, PP woven bag / PP non woven fabric washing and granulation machine, PE PP rigid washing and granulation machine, PET bottle washing and granulation machine, parallel twin-screw granulation recycling machine.

Our machines are specialized in processing PP PE PET PA PVC ABS PS EVA, etc. POLYTEC exported high quality machines to customers from various countries in the passed years, such as USA, Mexico, Australia, Croatia, Spain, Oman, KSA, Cameroon, Swaziland, Ethiopia, India, Bangladesh, Vietnam, etc.

We insist on the following principles: continuous innovation on technique, strict quality control, perfect service and reasonable price.

Quality is the soul of an enterprise. We always put quality as the first consideration.

Welcome to visit our factory at your convenience!