PET Bottle Crushing & Washing Line

POLYTEC Machinery provides PET Bottle Washing Line (500-3000KG/H) which is specifically used for recycling, crushing and washing waste PET bottles and other PET plastic bottles.

Features:

1. Recycled material: Total impurity content ≤320PPM; Moisture content≤2%

2. Capacity: 500-3000Kg/h ( But if lower than 500Kg/h, there will be no label remover machine, as the lowest capacity for label remover is 500Kg/h.)

Post-consumer PET bottles are doubtless among the most important components of the recycling market.Recycled PET may be used in a wide variety of final applications, with very interesting and remunerable financial returns for the recycling companies.

As the quality of the collected PET bottles varies significantly from country to country, and even within the same country, and as their conditions can be very bad, it is necessary to be continuously updated on the technologies and technical solutions of PET recycling,in order to correctly process the most difficult and contaminated materials and reach the best final quality.

POLYTEC Machinery,thanks to its worldwide experience in the field of PET bottle washing line and recycling line, can provide its customers with proper technical solutions and state-of-the art recycling technologies, delivering a response tailored to the frequently changing needs of its customers and of the market.

PET Flake Quality Reference Table:

Moisture Content | <0.9% | Label | <20ppm |

PVC | <50ppm | Variegated tablets | <30ppm |

Glue | <10ppm | PH | Neutral |

PP/PE | <20ppm | Total impurity | <100ppm |

Metal | <20ppm | Flake size | 12mm, 14mm or according to customer needs |

According to the final usage of PET flakes, POLYTEC's PET recycling and washing system divides into 4 categories:

1. Bottle to bottle grade, PET bottles recycling and washing line

2. Yarn/filament grade, PET bottles recycling and washing line

3. PSF grade, PET bottles recycling and washing line

4. Regular grade, such as strapping, brusher making, etc., PET bottles recycling and washing line

Features:

1. Recycled material: Total impurity content ≤320PPM; Moisture content≤2%

2. Production Capacity: 300-1000Kg/h ( But if lower than 500Kg/h, there will be no label remover machine, as the lowest capacity for label remover is 500Kg/h.).

3. Note: We can design the machines exactly according to Customers' requirements. If want to know the details for this machine, just feel free to contact us, send us your inquiry.

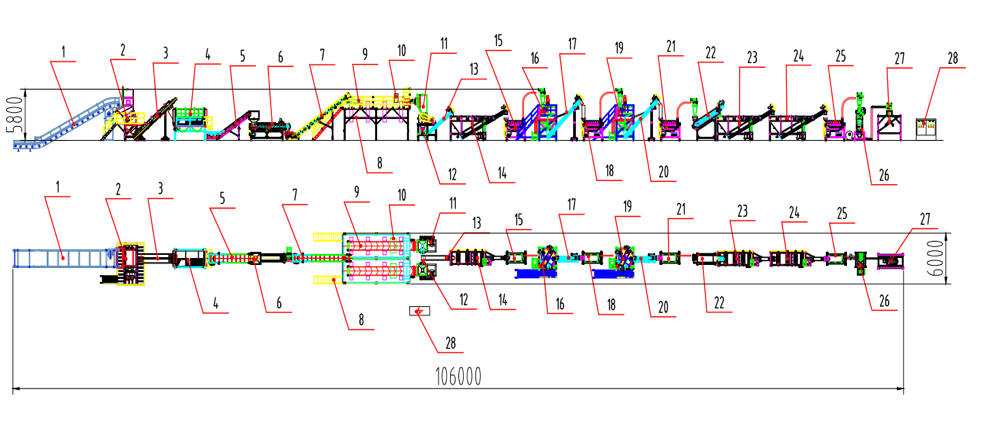

Equipment lay out drawing

Equipment list and price

No. | Name | Qty. |

1 | Metal chain conveyor (sink into the ground) | 1 |

2 | De-baler | 1 |

3 | Double screw loader(with silo) | 1 |

4 | Trommel | 1 |

5 | Belt conveyor | 1 |

6 | Label remover | 1 |

7 | Belt conveyor | 1 |

8 | Steel table | 1 |

9 | Manual sorting table | 2 |

10 | Metal detector + automatic separation device | 2 |

11 | Crusher | 2 |

12 | Horizontal screw conveyor | 1 |

13 | Screw loader | 1 |

14 | Floating washer ( with sliding ladder) | 1 |

15 | High speed de-watering machine | 1 |

16 | Steam washer (Including working platform) | 1 |

17 | Screw loader | 1 |

18 | High speed de-watering machine | 1 |

19 | Steam washer (Including working platform) | 1 |

20 | Screw loader | 1 |

21 | High speed de-watering machine | 1 |

22 | High speed friction washer | 1 |

23 | Floating washer | 1 |

24 | Floating washer | 1 |

25 | Centrifugal dewatering machine | 1 |

26 | Zig-zag label blower | 1 |

27 | Silo | 1 |

28 | Electric cabinet | 2 |

Parts Photos

Spare parts lis

Item | Name | Quantity | Price(USD) |

1 | Bearing for belt conveyor | 6pcs | FREE |

2 | Tungsten steel blade of label remover | 15pcs | |

3 | Belt of label remover | 1 piece | |

4 | Belt of crusher | 1 piece | |

5 | Crusher screen | 1piece | |

6 | Screw for crusher blade press | 50pcs | |

7 | Chain for screw feeder | 1piece | |

8 | High speed friction wash belt | 1pcs | |

9 | High speed de-watering machine belt | ||

10 | Contactors which is less than 15am | 2pcs | |

11 | Relay which is less than 15am | 2pcs | |

12 | Maintenance tool | 1set |

Estimated Plant Parameters:

| Capacity(kg/h) | Power Installed(kw) | Required Area(m2) | Manpower | Steam Volume(kg/h) | Compressed Air(m3/min) | Water Supply(m3/h) |

| 500 | 220 | 400 | 8 | 350 | 4 | 1 |

| 1000 | 500 | 750 | 10 | 500 | 10 | 3 |

| 2000 | 700 | 1000 | 12 | 800 | 15 | 5 |

| 3000 | 900 | 1500 | 12 | 1000 | 15 | 6 |

| 4500 | 1000 | 2200 | 16 | 1300 | 18 | 8 |

| 6000 | 1200 | 2500 | 16 | 1800 | 18 |

About our service:

PET Bottle washing line Before-sale

1、Introduce products and applications detain

2、Recommend suitable solution

3、Provide with reference information

4、Offer lab for test

During Manufacturing

1、Provide with layout and engineering conditions

2、Inform the project processing status

3、Offer other documents

After-sale

1. Provide with installation, commissioning and training

2. Register and record customer information

3. Offer spare parts

4. Provide with necessary technical support for new application

5. Visit customer regularly and correct information

Why choose us

1.Lower investment cost for a high quality and durable machine;

2. Low energy consumption with high production output;

3. Overseas installation and training are available;

4. Machine warranty with spares in stocking and in-time delivery;

5. Fast machine delivery and installation: POLYTEC produces on an average of 10 sets of plastic machines per month and can deliver the machine faster than most manufacturers. The regular delivery time of an POLYTEC recycling machine is 60 days.